Description

Argument

Products Description

Innovate spraying technology, define a new benchmark for precision and efficiency

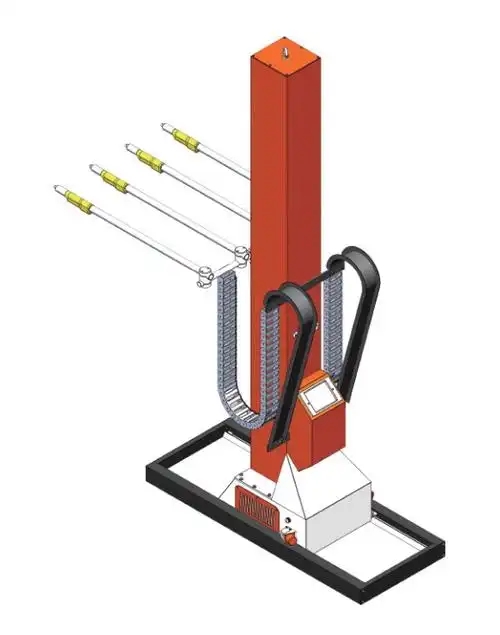

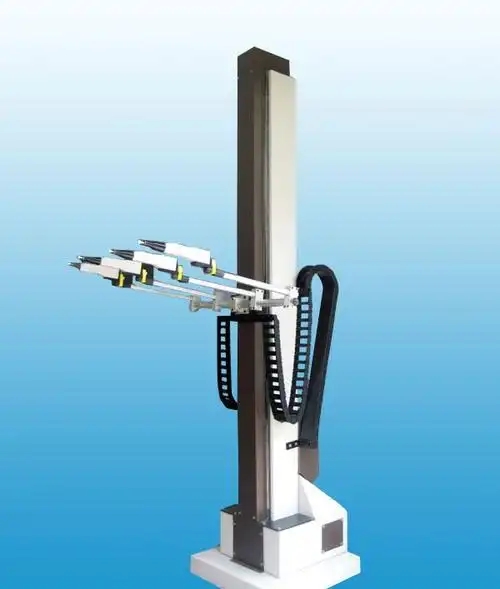

The spraying auxiliary equipment - reciprocating machine, as the core execution unit of the spraying production line, provides specialized spraying solutions for fields such as automobile manufacturing, home appliance accessories, hardware products, furniture decoration, etc., with precision reciprocating motion and intelligent control as the core. The equipment integrates high-precision transmission, modular design, and intelligent driving technology to achieve uniform coating spraying and efficient coverage, helping enterprises improve coating quality and production efficiency.

Core advantage, driving the upgrade of spraying efficiency

1. Precise reciprocating motion ensures uniform spraying

High precision transmission mechanism achieves stable reciprocating motion of the spray gun, ensuring consistent coating thickness

Integrated control system, real-time adjustment of spraying speed and stroke, adapting to different workpiece requirements

High precision in repeated positioning, reducing spray overlap and missed spraying phenomena

2. Intelligent control to improve spraying quality

Support programming control, can preset multiple spraying trajectories and parameters

Real time monitoring of spraying status, automatic adjustment of spray gun angle and flow rate

Compatible with multiple types of coatings to meet different surface treatment requirements

3. Stable and durable, reducing maintenance costs

Made of high-quality materials, with a long service life and excellent precision retention

Modular design, low failure rate, easy maintenance

Compatible with multiple driving methods to meet the needs of different production environments

4. Flexible adaptation to meet customized needs

Multiple specifications and travel options are available, suitable for spraying flat, curved, and irregular workpieces

Intelligent electronic control system, supporting variable frequency speed regulation and multi-stage speed control

Compatible with MES/ERP systems to achieve real-time interconnection of production data

5. Safety and environmental protection, safeguarding sustainable production

Fully enclosed protective design reduces paint splashing and dust pollution

Equipped with emergency braking and safety interlock devices, in compliance with safety standards

Low noise operation, creating a comfortable working environment

Application scenarios, covering the needs of the entire industry chain

Automobile manufacturing: precision spraying of exterior components such as body parts and bumpers

Home appliance accessories: Decorative spray coating on the outer shells of refrigerators, washing machines, etc

Hardware products: anti-corrosion spraying of metal parts such as door handles and locks

Furniture decoration: surface spraying and protection of wooden and metal furniture

Industrial equipment: protective spraying of mechanical equipment, pipelines and other components

Why choose our spraying auxiliary equipment - reciprocating machine?

Professional services: providing full process technical collaboration from solution design to installation and debugging

Quality commitment: Long term warranty for core components and global service network coverage

Delivery guarantee: Standardized production processes to shorten project delivery cycles

Language support: Multi lingual technical team to eliminate cross-border communication barriers

Drive industrial upgrading and create triple value

We are committed to helping businesses achieve:

Improved spraying efficiency and shortened order delivery cycle

Improved consistency of coating quality and reduced rework rate

Optimizing production costs and enhancing product market competitiveness

Upgrade the level of intelligence and connect with Industry 4.0 production lines

Contact us now to customize your intelligent spraying solution

Whether you are upgrading your existing spraying production line or planning to build a new intelligent spraying factory, our expert team will provide you with:

Free process optimization consultation

Customized equipment integration solution

Guidance on energy-saving renovation and energy efficiency optimization

Global logistics and operational training support

Tags: Reciprocating machine

Technical parameter

High-temperature curing furnac

Large scale dust collector ins

Mining specific dust removal e

Vertical spraying production l